soil stabilisation

Soil treatments are soil improvements, qualified soil improvements (soil improvements with stricter requirements) and ground stabilisation with binders. They are used in earthworks and road constructions. For soil improvement purposes standardised binders as well as mixed binders according to the information sheet for the manufacture and application of mixed binders, are used. Soil treatments are economic processes saving natural resources (e. g. gravel, chippings) and enable the recycling of inappropriate soils.

Whilst soil improvement is beneficial for conditioning soils there may be limited strength increase. To improve strength it is necessary to go to a second stage termed soil stabilisation.

The requirements for soil improvements and the places of application are defined in the German Standards ZTV E-StB and ZTV Beton-StB and RStO. Suitability tests are necessary for soil improvements with binders. The suitability of soil improvements, qualified soil improvements and soil stabilisatins have to be verified according to TP BF-StB, part B 11.3 "Eignungspruefung fuer Bodenverbesserungen". Suitability tests according to TP BF-StB, part B 11.1 "Eignungspruefung fuer Bodenverbesserungen" have to be carried out for soil stabilizations in earthworks. Hydraulically bound base course layers have to be tested according to TP Beton-StB. The new testing regulations TP BF-StB, part 11.1 and TP BF-StB, part 11.3 include guidelines and work instructions for soil tests, tests of the soil-binder-mixtures and tests of the binders, related to the required strength and frost-resistence. They also provide recommendations for the use of hydraulic binders, lime and mixed binders. They replace part B 11.1 "Eignungspruefungen fuer Bodenverfestigung mit hydraulischen Bindemitteln", and part 11.5 "Eignungspruefung bei Bodenverbesserung und Bodenverfestigung mit Feinkalk und Kalkhydrat". The new part B 11.3 includes compaction tests and strength tests to prove the required bearing capacity of subsoils or backfill material consisting of fine and mixed grained soils.

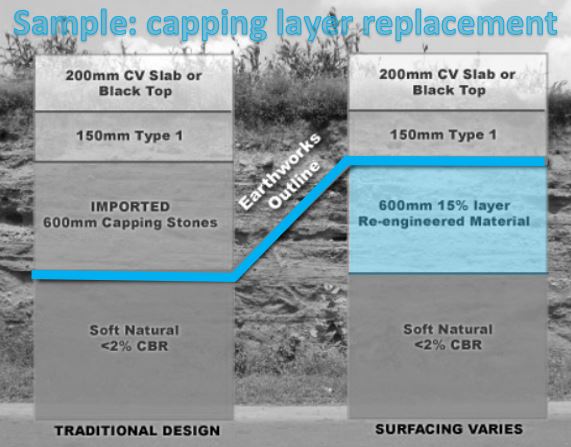

Sample: Re-engineered Material: Soil Stabilisation - Soil Consolidation - Soil Improvement with Additives

Soil Stabilisation, soil improvement and soil consolidation have a wide range of benefits and attractions in today's not only limited to road construction works.

The main advantage for "re-engineered material" is to reduce the earthworks outline levels and up to the main target, to minimise construction costs and speed up the work progress.

Our addititive is not binding material like cement or lime. Instead, it need only be present in the soil to provide a more compact bedding and almost entirely prevent subsequent swelling. Moisture and frost have no effect together with the cement or lime. The additive reduces the surface tension of the water around the soil particles so that the barrier film surrounding the particles is dispersed in order for the surfaces of the particles to associate to each other. This causes an agglomeration of fine and improves certain soil characteristics through the frost resistance effect together with the optimised clinker phases to the cement.

In additional, together with our additive, your road will be up to 1$/m2 cheaper, by saving a high cement content in a approved system. Cement savings from 50% to 70% are common.

The process of lime modification and soil stabilisation with cement consist by road construction the following unsuitable subgrade material (CBR< 2):

|

|

The lime improvement with small amounts of uncalibated lime to reduce moisture content transforming the wet/unsuitable material into a useable and compactable construction material with a design target of only 5% CBR.

To enable the formation of a capping replacement layer, binders and our additive are incorporated into the host material along with the addition of water. The material is then compacted in layer with a 15% CBR or exsample a capping layer replacement.

A subbase layer replacement for an examplele for an additional binders are incorporated into the material giving a stronger, more durable end product with frost resistance creiterias with a minimum target of 25% CBR soaked (40%CBR), additional the thickness of the base layer can be reduced.

You cannot compare directly the German standards, like RStO, ZTV or TP (technische Prüfvorschrift) direct to other standartds, but the princip of engineering is always the same.

The American Standard called "AASHTO" responsible is the American Association of State Highway and Transportation Officials.

Soils improved with fine ground lime and cement have established themselves in construction work already. This is not just ultimately based on soil values which can actually be measured.

Almost any available soil can be produced frost resistant or by higher bearing capacity, combined with the advantages of a lower cement content and our soil improver to keep construction costs as low as possible.

The replacement of soil unable to bear a load under moisture and frost is no longer required, costs can be reduced and unnecessary transport can be avoided.

This is an active contribution to cost reduction and protection of the environment, within an approved method and specification in the country of execution.

Advantages in comparison with the adapted traditional soil stabilisation:

- Most favourable method for the standardised soil consolidation in the mixed in place and mixed in plant method

- The additional costs of the additive are more than compensated by savings in binding agents up to 60%

- Savings of 25% of the total costs for conventional soil consolidation with "cement only" are realistic

- Strong reduction of water absorption through reducing the capillary activity

- The Proctor Optimum of treated soil is lower and the density is higher

- Strong reduction of water sensibility

- Reduced swelling and shrinking behaviour

- The TS System is a high-tech soil stabilization and soil waterproofing that is different from the traditional methods as it makes soil compaction with hydraulic binders totally irreversible

- Decreasing the carbon footprints by replacing crushed materials

- Perfect for immobilisation of existing contaminations in soils

- Fits to tropical regions, as well to the criterias of frost resistance for cohesive soils in northern countries

Economical:

The improvement of properties as well as the soil bearing values is permanent and an upgrading can be observed in a short time with the effects of traffic. The increasing firmness and stability of the treated soil will bring about longer durability and thus bigger savings due to less maintenance.

As the soil takes part as a lead actor, the application of the TS System is very simple. The same amount of additive is required for almost any soil to get the desired result. The other strong points of TS System are:

- Simple application made with the pool of available machinery

- Subbase Layers can construct with existing Soil up to the frost resistance criterias

- Base layers with high cohesive amounts can be used for road construction

Environmentally friendly:

The permanence and increasing stability of the treated soil yield a higher durability and thus additional savings thanks to lower maintenance costs.

The TS System works with the same with any kind of soil, as it activates the cohesive forces of the soil and substantially and lastingly reduces the influence of the water. The TS System modifies soil in its own permanently and thus can be used insitu or in a premixing procedure at a plant. Once added to the soil, it maintains the effect of the system.

The TS System is high tech soil stabilisation and soil waterproofing that is different from the traditional methods as it makes compaction totally irreversible.

Simple application made with the pool of available machinery.

TS is based on natural chemical substances, which breaks up the adhering water film and leads to an irreversible agglomeration of fines, reducing the capillary rise of water substantially. The high effectiveness of TS protects the soil, especially against the soaking in of water. It allows better compaction of the treated soil and increases desired density during the time and under traffic.

Characteristics:

- Better compactibility through changing the water characteristic in the soil

- Strong reduction of water absorption through reducing the capillary activity

- The Proctor Optimum of treated soil is lower and the density is higher

- Strong reduction of water sensibility

- Reduced swelling and shrinking behaviour

The high effectiveness of TS protects the soil, especially against the soaking in water. It allows better compaction of the treated soil and increases desired density during the time and under traffic.

Soil-own humic acids and fulvic acids, which negatively influence the setting behaviour, are minimized by ion exchange reactions.

The agglomeration of the finest components increases the paving capability, compaction energy is minimized and the paving positions can be increased analogously.

We cannot replace limes and cements, but we can significantly improve their binding properties with earth materials together with our additives.

Dosage:

In additional to the lower amount of the hydraulic binders, 0.4 up to 1.6 litres of the additive is applied to 1m3 to the soil.

The exact amount of the mixture is depending from the optimum moisture contents of the soil. The fixed dosage of the additive is 1:175 in water of the optimum Proctor density of the stabilized soil.

An Excel form is available in our download area to determinate the amount of the additive with the soil condition on site.

Price:

Our selling price is the lowest, ex works Recke in Germany plus transport to the customer.

International orders only in IBC's.

For further details as well as customer discounts and payment methods, please contact Mr. Nils Pohlmann at Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!.

Advantages for the soil Stabilization with our additiv:

- Stabilization for desert sand (round particles) possible.

- Savings of up to 60% of the cement content.

- Minimal costs due to the additive.

- Minimization of transport routes and costs.

- Less expensive than comparable conventional soil stabilization systems.

- Resistant to moisture penetration. -Even without top coats /pavings.

DESIGN PROCEDURES FOR SOIL MODIFICATION OR STABILIZATION

It is our policy to minimize the disruption of traffic patterns and the delay caused today’s motorists whenever possible during the construction or reconstruction of the State’s roads and bridges. INDOT Engineers are often faced with the problem of constructing roadbeds on or with soils, which do not possess sufficient strength to support wheel loads imposed upon them either in construction or during the service life of the pavement. It is, at times, necessary to treat these soils to provide a stable subgrade or a working platform for the construction of the pavement. The result of these treatments are that less time and energy is required in the production, handling, and placement of road and bridge fills and subgrades and therefore, less time to complete the construction process thus reducing the disruption and delays to traffic.

These treatments are generally classified into two processes, soil modification or soil stabilization. The purpose of subgrade modification is to create a working platform for construction equipment. No credit is accounted for in this modification in the pavement design process.

The purpose of subgrade stabilization is to enhance the strength of the subgrade. This increased strength is then taken into account in the pavement design process. Stabilization requires more thorough design methodology during construction than modification. The methods of subgrade modification or stabilization include physical processes such as soil densification, blends with granular material, undercutting and replacement, and chemical processes such as mixing with cement, additives.

Soil properties such as strength, compressibility, hydraulic conductivity, workability, swelling potential, and volume change tendencies may be altered by various soil modification or stabilization methods. Subgrade modification shall be considered for all the reconstruction and new alignment projects. When used, modification or stabilization shall be required for the full roadbed width including shoulders or curbs.

Laboratory testing

Chemical Modification or Stabilization

The transformation of soil index properties by adding chemicals such as cement, fly ash, lime, or a combination of these, often alters the physical and chemical properties of the soil including the cementation of the soil particles. There are the two primary mechanisms by which chemicals alter the soil into a stable subgrade:

1. Increase in particle size by cementation, internal friction among the agglomerates, greater shear strength, reduction in the plasticity index, and reduced shrink/swell potential.

2. Absorption and chemical binding of moisture that will facilitate compaction.

Standards testing has to be taken out in advance to comply to specified standards. The determination can be executed by AASHTO T 153/ T136, based on durability tests on ASTM D 559 and D 560 or other local standards to comply to the specified standards of the country. For EU and Germany, the main specifications are ZTV E StB, ZTV Beton-StB and BF-StB.

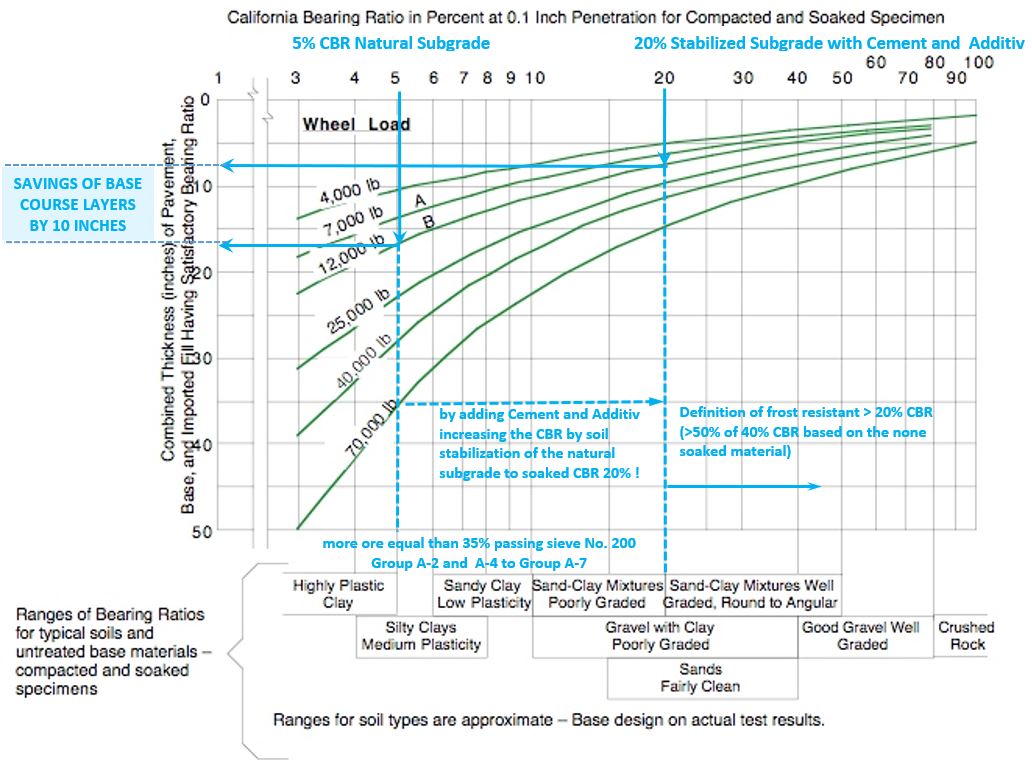

Special the stabilization of silty-clay materials (more ore equal than 35% passing sieve No. 200) Group A-2 and A-4 to Group A-7 is recommended to archive the criteria for subgrade, subbase and up to base criteria. Savings can be made in the thickness of the mineral layers.

The frost resistance is additional to the required CBR defined by a min. soaked CBR from 40% after soil stabilization when cement is used.

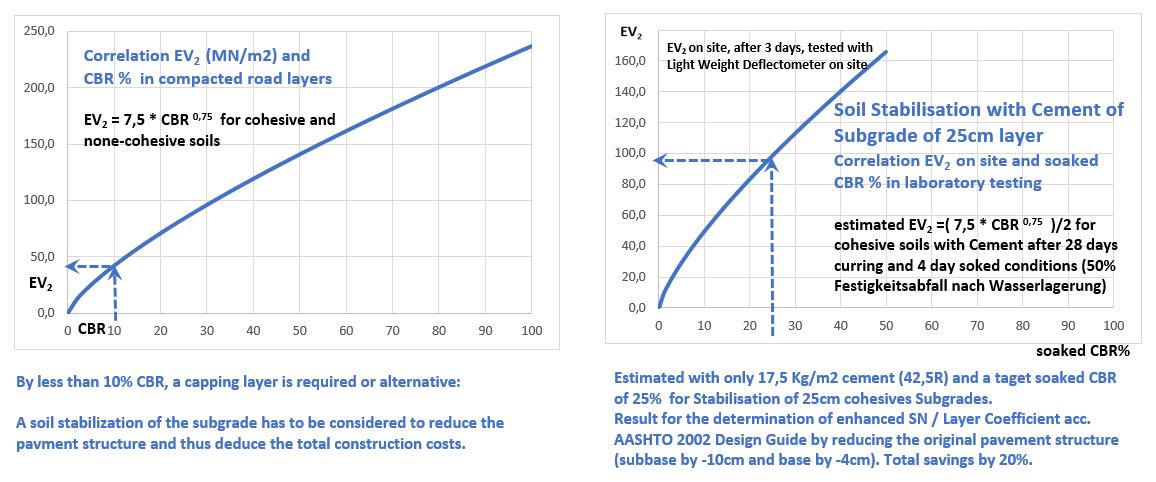

Correlation CBR / EV2

EV2 = 7,5 * CBR 0,75 for cohesive and none-cohesive soils, Relationships between CBR value and deformation module Ev2 (WEINGART, 1998)

is useful under the soaked condition for a soil stabilisation. This means an EV2 about 70 MN/m2 is equivalent to a CBR of 20% under soaked condition in no frost areas and a EV2 about 120 MN/m2 is equivalent a CBR of 40% for frost areas of the bounded compacted soil has to be reached on site. It's simple to check on site with a light weight deflectometer according to ASTM E2835-11.

Pavement Design Example 1

Example of soil stabilization, for weak Subgrade:

The existing CBR, on the not stabilized subgrade is 5%, after soil stabilisation with 3% cement with additive (after 28 days curing), the CBR increase to 20%, to be tested under soaked conditions 24h under water. The design of the content of cement has to be carried our to a CBR to 40% "called frost resistant" by a standardised soil stabilization (50% of the reached CBR under soaked condition with 20% CBR is required).

The Target is to reach the "dry" CBR of 40% in no frost areas, further the "dry" CBR of 80% in frost zone areas has to be reached on specimen condition. The content of cement or hydraulic binders has to specificed by laboratory testing in advance. With our additive, a content of 3% cement will reach the criterias.

Design thickness of 10 inches of the soil stabilisation (compactable in 1 layer within the mixed in place method). No compaction of the lower fill / lower subgrade (fictive formation level) is required when a soil stabilization is carried out in a thickness of min. 10 inches.

Question:

How much pavement (reducing thickness of mineral layers) or base course layers can we save, when we using a soil stabilization to the subgrade?

Method:

From the below chart for given CBR value of soil subgrade and Wheel load value select appropriate thick curve value of “combined thickness of surface, base and sub-base line” which will give the total thickness of pavement.

With our additives we increase the CBR value of the subgrade, in a simple way with called "soil stabilisation".

Determination the thickness of Pavement acc. to the California Bearing Ratio (CBR) of the Subgrade, under soaked specimen condition

Answer:

up to 10-inch mineral layer can be saved, by using an additional soil stabilization of 10 inch when the soaked CBR reached by a stabilisation method 20%.

Savings:

- 10-inch base course= 10 USD minus 2 USD for soil stabilization of the subgrade with additives

- 8 USD per m2 plus disposal costs, transportation of 10 inches earthworks materials can be saved

- 20% more favourable though savings of binding agents than a soil stabilization (soil consolidation) "with only cement"

- up to 70% of cement savings

For further information, including a draft presentation of our product, can be found on "Downloads"

Pavement Design Example 2

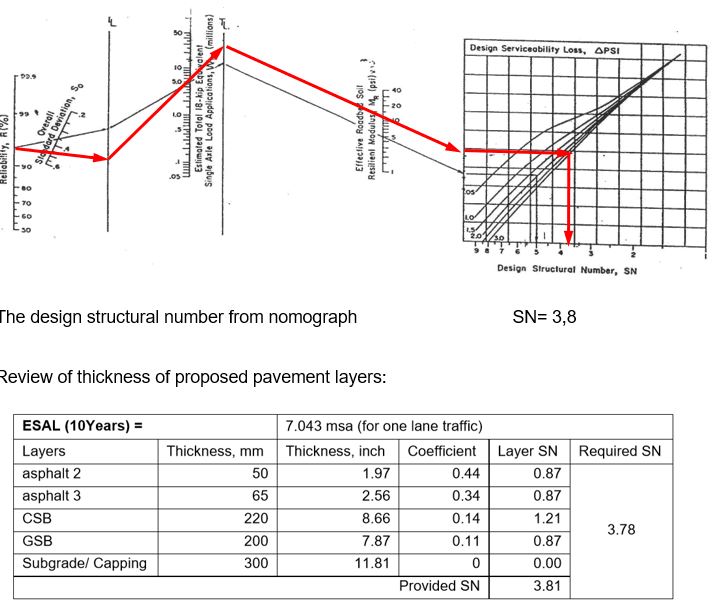

Original Pavement design with out soil Stabilisation of Subgrade

Draft determination of SN / Layer Coefficient

Reliability factor R = 0.95%

Overall standard deviation So = 0.45 for flexible pavement

Resilient modulus of sub-grade for a CBR of 10% MR = 11.150(psi)

Based on the “AASHTO 2002 Design Guide” with MR= 2555 x CBR0.64 with MR= 2555 x 10 0,64 = 11.152 psi, equal with an min Ev2 of 45 MN/m2 on sub-grade to European standards.

Single Axle Load Application W18 = 14 Mio. Msa = 7 Mio Msa/Lane

Design Serviceability Loss delta PSI = Po-Pt=2,5-0,0=2.5 (min. required)

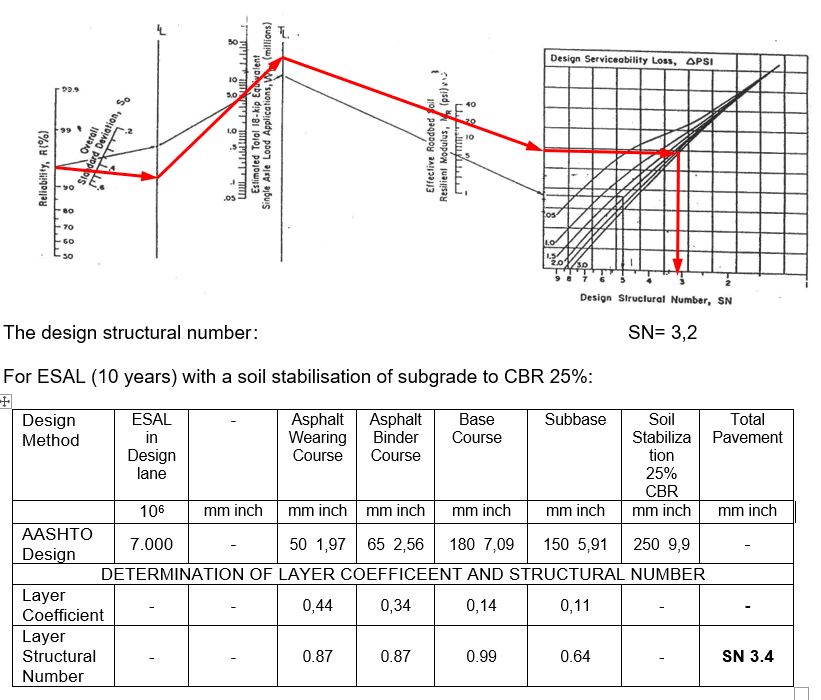

Suggestion for improvements on existing pavement design with soil Stabilisation of Subgrade

Soil stabilisation, soil improvement and soil consolidation within the Mixed-in-Place Method or Mixed-in Place have a wide range of benefits and attractions in today's road construction works.

Due to the soft ground in phase II, and unsuitable soil which has to be replaced by suitable fill material, a soil stabilisation would be possible by adding a small amount of cement. The aim is to increase the soaked CBR value to 25% of the subgrade. The consolidated layer should be approx. 25 cm.

Without changing the design criterias of the original pavement design by adding a soil stabilisation to the subgrade, it causes a reduction of the SN value and thus a reduction of the layers of the road structure.

Further advantages would be:

- No Capping-layers required.

- No geotextiles as a filter layer are required.

- Reduction of the subbase thickness.

- Reduction of the base thickness.

- Haulage minimalization.

- Cohesive oversaturated soils can get stabilised with quick lime/cement

- No unsuitable material due to "re-engineered material"

- A more cost-effective construction method.

- Lower carbon dioxide emissions compared to conventional construction method.

The main advantage is to reduce the earthworks outline levels and to reduce construction costs and speed up the work progress.

The design target shall be for phase II to stabilization of the existing subgrade (cohesive soils, silty material) to a soaked CBR of 25%. The exact amount of cement shall be carried out in laboratory tests.

Draft calculation with soil stabilisation and original applied design parameters:

Calculation of the Resilient modulus of stabilised sub-grade for a target CBR of 25%

Based on the “AASHTO 2002 Design Guide” with:

MR= 2555 x CBR0.64 with MR= 2555 x 25 0,64 = 20.048 psi

Draft Structural Number (SN) by soil stabilisation of the subgrade layer from nomograph:

Summarised:

With a soil stabilisation of 25cm to the embankment, base course can be reduced by 4 cm and additional the sub-base layer by 10 cm. No capping layer and geotextile is required.

correlation EV2, CBR and soaked CBR